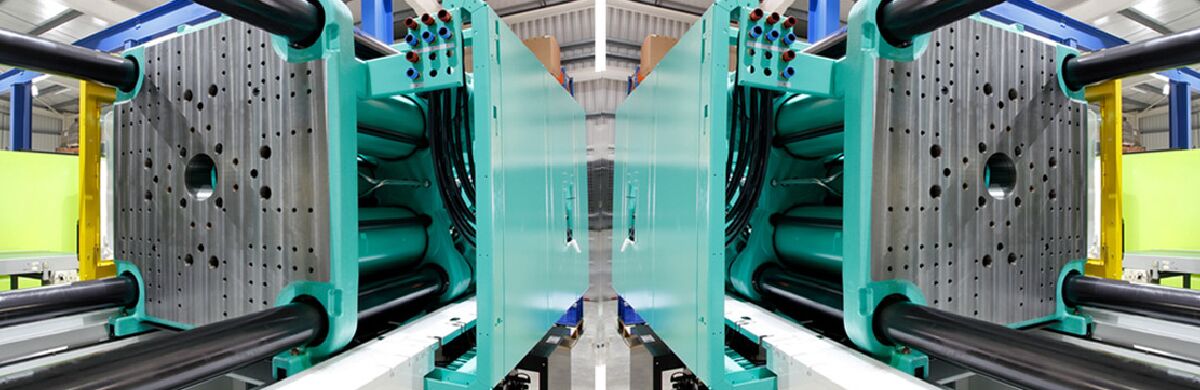

Plastic Injection Molding Service

At CNCTECK, we specialize in producing high-quality plastic injection molded parts and mold tools. We offer machining and finishing services to make tools from a variety of materials, and can produce 50 to 100,000+ finished parts in all a wide variety of plastics.

With advanced material verification, inspection and testing processes we can ensure your tools and parts exceed your expectations. If

you’re ready to start your next project, contact our injection molding team for a free quote today.

How Plastic Injection Molding Works

Plastic injection molding is by far the most common way to produce large volumes of

finished plastic parts for every kind of commercial and industrial use. Molten resin is

injected under high pressure into the cavity of a metal die and then rapidly cooled,

forming a solid shape. A single cycle to make a finished part may take anywhere from

a few seconds to minutes depending on part complexity and size.

The Plastic Injection Molding Process

Once your plastic injection mold tools are ready, the molding process consists of the following basic steps:

Step 1. The plastic resin comes in raw pellets. These are dried to the right moisture content, and then if

necessary they can be blended with pigments or master batch colorants.

Step 2. The dried pellets are poured into the hopper of the molding machine. A reciprocating screw inside

the barrel of the machine will transport these pellets towards the mold.

Step 3. Within the barrel, the pellets are mixed and heated until fully molten, forming the liquid resin.

Step 4. The heated mold closes automatically and resin, under great pressure, is injected through a gate

and into the mold cavity.

Step 5. The mold is cooled to solidify the part inside.

Step 6. The mold opens and the part is ejected to begin a new cycle.

Rapid Tooling Service

We make hard tooling (cores and cavities) from a variety of materials to suit your

budget, order volume and time to production. We routinely make high-quality tools

from aluminum 7075-T6 for injection molding, while steel tooling made from P20,

NAK80 and H13 is available for volumes up to 100,000 pieces. Specialty metals can

also be ordered on request. Learn more about our rapid tooling service.

Plastic Injection Molding Tolerances

All plastic material will expand and contract under the influence of heat and moisture, Our tolerance guide will give more general information on the characteristics of most common resin types for typical part features.

We will work closely with you to optimize your designs for manufacturing. We will indicate any areas where poor design may produce thermal stress, shrinkage, warping, etc. Consult our design guide for more information on common defects and how to avoid them.

Unless otherwise specified, we comply with the DIN 16742 standard tolerances for plastic injection moldings. Read about the visual quality standards that we apply to injection molded parts.