Finishing Services

Surface treatment is an artificial layer of mechanical, physical and chemical properties on the surface of the substrate material. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special function requirements of the product.

You want your parts to look and feel exactly as you designed them to, so achieving the perfect finish is essential to your complete satisfaction. Our technicians and craftsmen are prepared to offer a full range of services, from anodizing to plating, polishing to plating, all with the most careful attention to detail. See how we ensure beautiful parts by reading about our different finishing services or Contact us to get your free quote.

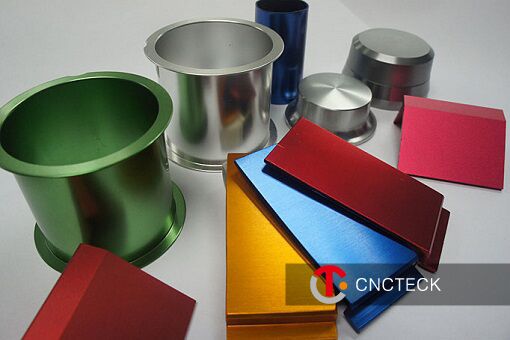

Anodizing

There are many reasons to choose anodizing on aluminum, magnesium or titanium.

Anodizing helps to resist corrosion, increase surface hardness, improve resistance to

wear and dissipate heat. Anodizing is an ideal surface treatment for painting and priming,

and it looks great too. We normally use Type II anodizing, which allows us to add tints or

dyes to your parts for a variety of visual effects. Type II is also available for surfaces that

need to be extra hard.

Painting

A great paint job is one of the best ways to make your product stand out from the crowd.

Using only the finest PPG automotive polyurethanes, we can replicate virtually any color,

tint or hue in our climate-controlled, automated spray room.

Our master painters can supply millions of colors, in matte, flat, semi-gloss or glossy

finishes. We even create custom painted textures. We also have the highest ISO and

BS certifications for quality and environmental protection so you can be rest assured that

you’ll receive only the most professional and responsible painting service.

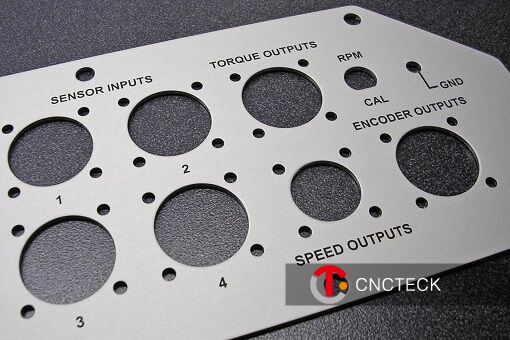

Printing and Etching

We have many ways to provide custom printing and marking of text and logos on your

parts. We make custom stencils for pad printing on most flat or curved surfaces. Pad

printing is fast, reliable, consistent and comes in many colors. Silk screening is also

available for larger surfaces and when mixing multiple colors for even more complex

graphics.

We can etch or engrave your graphics using an engraving tool, while laser etching is

ideal for making the most precise and permanent marks on metal and some plastics.

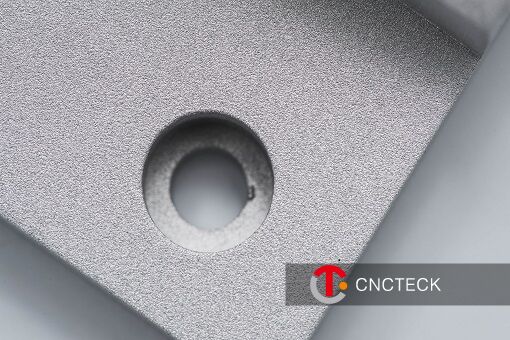

Sand Blasting

Blasting involves the controlled spraying of an abrasive media against the surface of your

part. A variety of media can be used, including sand, garnet, walnut shells, water or metal

beads.

Blasting is used to clean and deburr parts, preparing them both mechanically and chemically

for later surface finishes. Blasting also imparts unique textures, frosting, pebbling, etc.

Polishing

Polishing is the act of using a light abrasive product to remove a very thin layer from the surface that gets polished. Usually this process is preceded by a very thorough cleaning of the surface. There are products to polish paint, glass, plastic, Perspex, metal and other solids.

Polishing or paint correction can be done by hand or machine. Polishing by hand means that you more control, can get into smaller areas and can actually “feel” how the pad responds on the paint. Polishing by machine has the benefit that it works much faster, gets warmer and it’s easier to work on a bigger area.

Get Your Project Started Today

Still haven’t found the type of finish you want? If you have any other special requirements we pride ourselves on finding solutions for any of your custom needs. Contact us today for a free quote to get your next project started.